Madell Pick and Place Machines

| Technical Information |

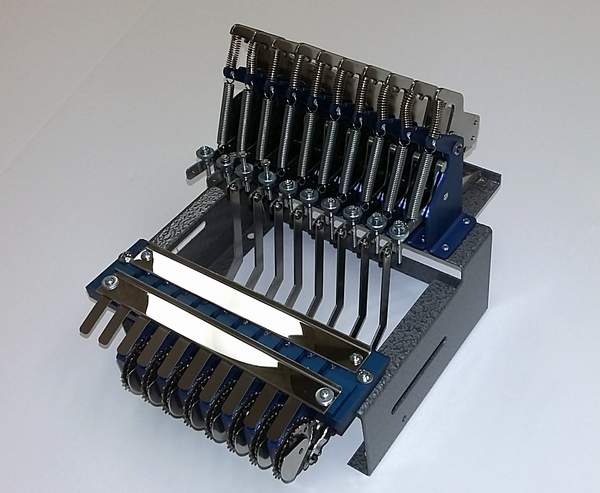

Feeders

Tape feeder: for parts on reel tapes. Specified by the tape width, like 8mm, 12mm,

16mm, 24mm etc.

We supply the following tape feeders:

1. PX feeder. faster and higher cost than SX series feeders, easy to set up and use.

2. SX feeder(obsolete). We invented the very low cost SX feeder in 2009. A puncher is installed

on the machine head. The puncher comes down to press on the tape and pulls

the tape forward. Computer vision is used to find the part on the tape

before it is picked up. Weights are used to peel the tape. The weights

have to be moved up manually from time to time. We do not offer SX feeders

anymore on new production machines. |

3. SX-2 feeder. X-2 feeder is the second generation of our low cost SX feeder. With the

SX-2 feeder, the tape is advanced at the same time that the part is picked

up. Computer vision is used to find the part on the tape as needed. The

tape is peeled automatically. No weights are necessary anymore. SX-2 feeders

are faster and work better for small parts than SX feeders.

|

SX-2 and SX-3 feeders

4. SX-3 feeder. Works similar as the PX feeder but lower cost. Tape advances with fixed

steps, either 4mm or 2mm. Faster and easy to use than the SX-2 feeder.

5. Programmable intelligent feeder: we also offer 3rd party programmable intelligent feeders

|

Vibration feeder: for parts packed in tubes. It is also called tube feeder.

|

Tray feeder: for parts packed in trays. No special feeder is necessary, just a fixture to hold the tray.

|

|

Up looking video camera

|

Up looking video cameras are used to align the picked part before it is

placed on the PCB. They are the eyes of the pick and place machines. The

view field of a video camera is fixed, and is suitable for a limited range

of part sizes. If a video camera's view field is good for small parts,

like 0402 , 0603, it will not be good for big parts. It probably can see

only a small portion of a big IC. Additional up looking video cameras have

to be used to cover different sized parts.

Smart Vision: our pick place machine software offers the self developed, easy to use,

unique and very powerful Smart Vision centering function. It greatly simplifies

and reduces pick place set up time. No template models or mask pictures

are required for Smart vision. It is in addition to mask picture vision

that also comes with our pick placce machine software. Our software also

offers license based model vision algorithm that is suited for irregular

shaped parts

High Speed Fly Over Camera: The pick place machines goes to the up looking camera to calculate the

X,Y and rotation shifts of the part picked up. This causes extra travel,

stop and pickture taken time. The machine does this calculation on the

way from the pick up location to the place location without stop if high

speed fly over camera is equipped. Overall machine performance is increased

about 1/3. The fly over camera is for small parts only, not for IC's.

|

High Resolution Digital Cameras

Our machines are equipped with 640x480 digital cameras. Available high

resolution cameras to upgrade your machine

(pixel arrays):

1280x960

1024x1024

1280x1024

1400x1024

1440x1080

1620x1236

2048x1088

1920x1200

2048x1536

2048x2048

2448x2048

2432x1728

3328x2502

4096x2160

4000x3000

4096x3072

10720x8064

|

Support:

Our new pick and place machines carry a one year standard warranty. We help our customers over the phone, email or video conference. We also offer extended software upgrade and technical support. |

|

|

|

|

|

|

|

|